Lianyungang Haosen mineral products Co., Ltd

Contact person: Manager Shi

Mobile phone: 17751885218

Tel: 0518-87255528

Fax: 0518-87255528

mailbox :923929950@qq.com

website: www.lyghskc.com

Address: No.7, Xuhai West Road, Donghai County, Lianyungang City, Jiangsu Province

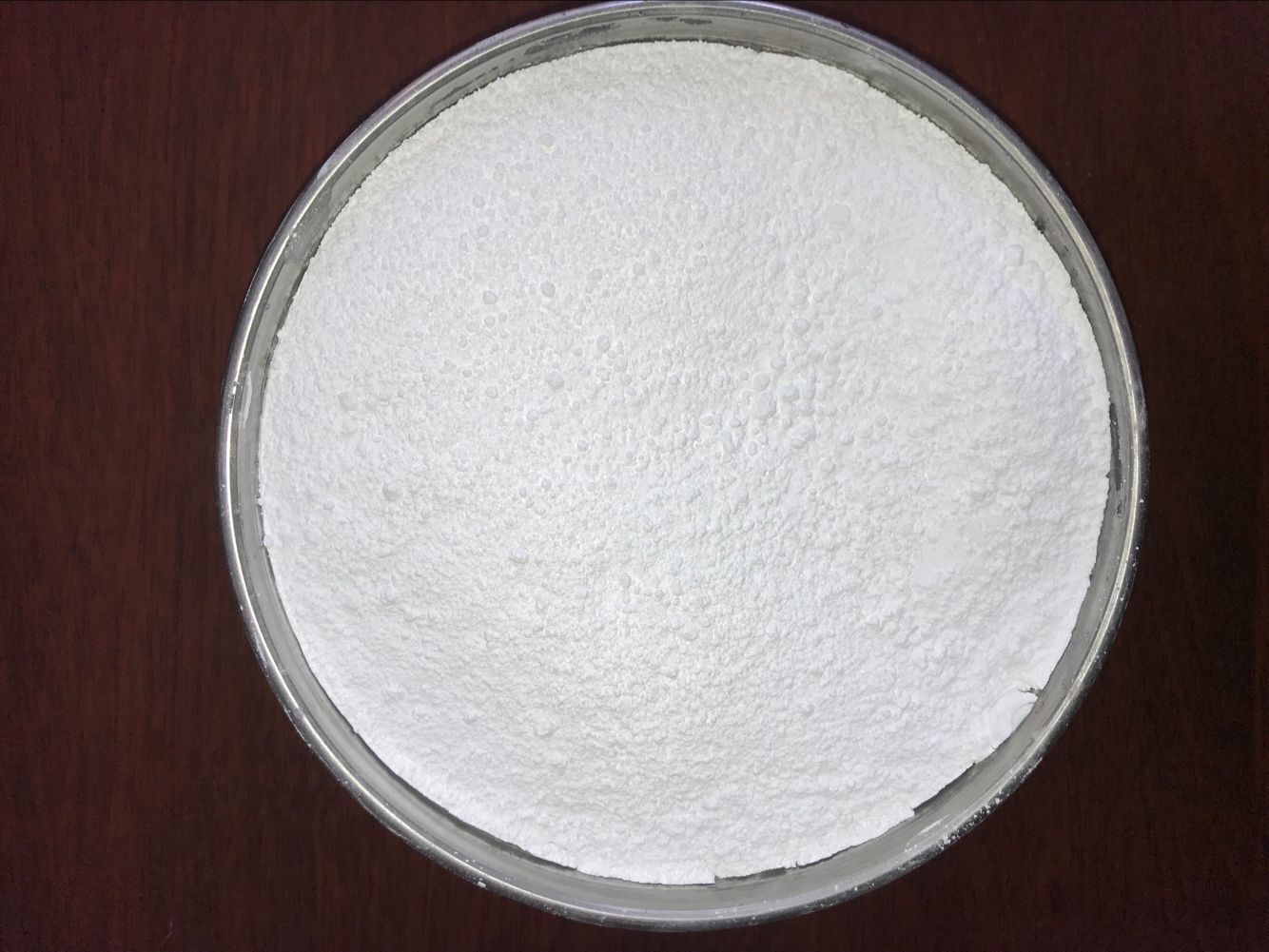

Nonmetallic mineral powder material is the main inorganic filler in CCL industry. The manufacturer mainly selects the corresponding filler according to the function of CCL. The common inorganic fillers are talc powder, aluminum hydroxide, alumina, ferric oxide, silica, etc. at present, the FR-4 CCL with large output mainly uses silica as filler.

In recent years, in the field of powder processing technology, powder surface modification is one of the technologies with active research and rapid development. The mechanism and method of powder surface modification, surface modifier, modification process and equipment, surface modification process control and product detection technology are the main research directions.

The demand for powder in CCL industry is increasing year by year, and it has become the fourth largest raw material. And the functional requirements of powder in CCL industry are very different from those in coating, rubber and other industries. The application trend of powder in CCL industry is mainly reflected in the following aspects:

The particle size is required to be smaller and smaller;

There are more and more kinds of powders;

More and more functional requirements.

All of these put forward higher requirements for powder modification technology. How to further study the modification process, modifier selection, modification equipment, process control and product detection technology to meet the needs of CCL industry has become the research focus of powder processing enterprises.

There are many purposes of powder surface modification, such as coatings, ink, engineering plastics, rubber, packaging adhesive, etc. each industry has different purposes and functions, but in the CCL industry, there are mainly the following aspects:

1. Improving the dispersion and compatibility of inorganic powders in organic materials

In the process of crushing and destroying inorganic minerals, the original crystalline state will be destroyed and the partial bond will be broken. New free radicals or ions will be produced on the surface of the powder, which will increase the surface energy of the powder and cause agglomeration between the powders, which is not conducive to the dispersion of the powder in the resin and solvent.

The smaller the particle size is, the larger the surface energy of the powder is, and the easier agglomeration occurs, which increases the difficulty of dispersion. The chemical reaction of surface modification can reduce the surface energy of the powder, improve its dispersion, and improve its compatibility with the resin.

2. Improving the activity of inorganic powder in organic material system

After surface modification, a layer of silane coupling agent is coated on the surface of the powder, and the silane coupling agent and the surface of the powder form a non random chemical bond, and some unreacted coupling agents are physically wrapped on the surface of the powder.

Because of the good compatibility between coupling agent and organic resin and the decrease of the viscosity of the glue, the activity of the powder in the glue increases

On the one hand, it is convenient for CCL customers to adjust the characteristics of glue solution to meet the requirements of gluing process;

On the other hand, when the prepreg is pressed, because the powder activity is good, the average of the prepreg is better.

3. Enhancing the interfacial bonding between inorganic powder and organic polymer materials

The free radicals or ions on the surface of the powder will form some functional groups which react with organic matter under the action of water and air. For example, Si and Al in common silicate materials easily form active functional groups of Si oh and Al oh. These functional groups can react with modifier to form relatively undisturbed chemical bonds, such as si-o-r and al-o-r, which can make the powder and coupling agent combine strongly. Another functional group of coupling agent combines with organic resin to produce undisturbed structure.

4. Improve some characteristics of CCL, such as hydrophobicity, heat resistance and so on

Some properties of CCL can be improved by selecting coupling agents with different functional groups. For example, amino coupling agent can increase the curing reaction of epoxy resin; modifier with hydrophobic groups such as alkyl group can improve the moisture resistance of CCL.

In short, due to the increasingly fine particle size requirements, more and more types of powder, and diversified functional requirements of the copper clad laminate industry, surface modified powder has become the trend of use in the copper clad laminate industry.

At present, most of the powders with larger particle size less than 11 μ m are treated by surface modification, otherwise they cannot be stored and used well.

Lianyungang Haosen Mineral Products Co., Ltd

Contact person: Manager Xu 158 6125 0533

Manager Shi 152 5244 5528 177 5181 8818

Tel: 0518-87255528

Fax: 0518-87255528

Email: 923929950@qq.com

Website: www.lyghskc.com

Address: No.7, Xuhai West Road, Donghai County, Lianyungang City, Jiangsu Province