Lianyungang Haosen mineral products Co., Ltd

Contact person: Manager Shi

Mobile phone: 17751885218

Tel: 0518-87255528

Fax: 0518-87255528

mailbox :923929950@qq.com

website: www.lyghskc.com

Address: No.7, Xuhai West Road, Donghai County, Lianyungang City, Jiangsu Province

Fused silica

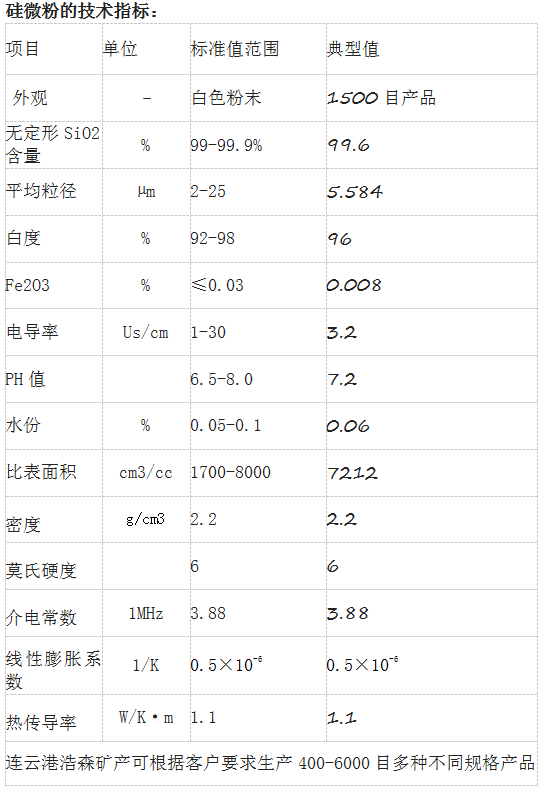

【 Product Introduction 】: Fused silica is a type of silica powder made by using natural high-quality quartz, melting at high temperature, cooling amorphous silica as the main

raw material, and processing it through a unique process.

This product has high purity, low coefficient of thermal expansion, low internal stress, high humidity resistance, and low radioactivity. And as a plastic sealing material for closed

integrated circuits, it has outstanding advantages such as good mobility, less overflow, and large filling capacity.

【 Application Scope 】: Molten silicon micropowder has a wide range of applications, mainly used in industries such as electronic packaging, investment casting, advanced electrical

insulation, paint coatings, silicone rubber, refractory materials, advanced plastics, special ceramics, etc.

【 Main features 】:

1. Extremely low coefficient of linear expansion and low internal stress

2. The product has high purity, good whiteness and uniform particle size distribution;

3. Good electromagnetic radiation

4. Low ion content, low conductivity, and excellent electrical insulation;

5. Stable chemical properties, high humidity resistance;

6. Acid and alkali resistance, high temperature resistance, and good insulation performance;

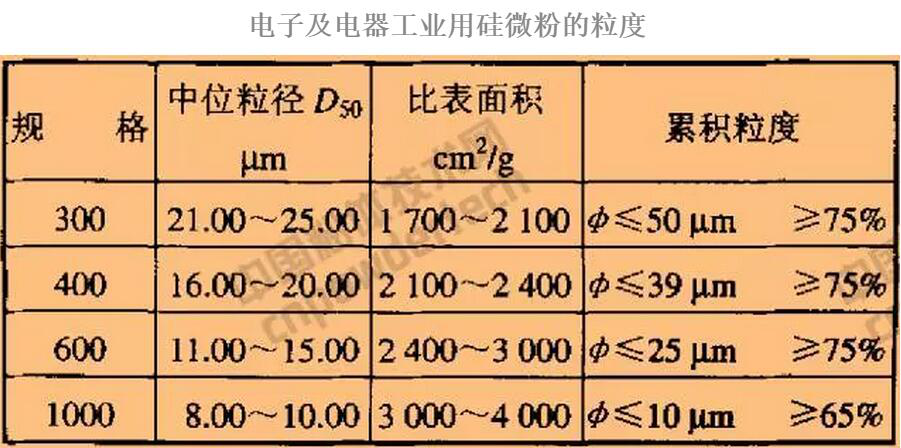

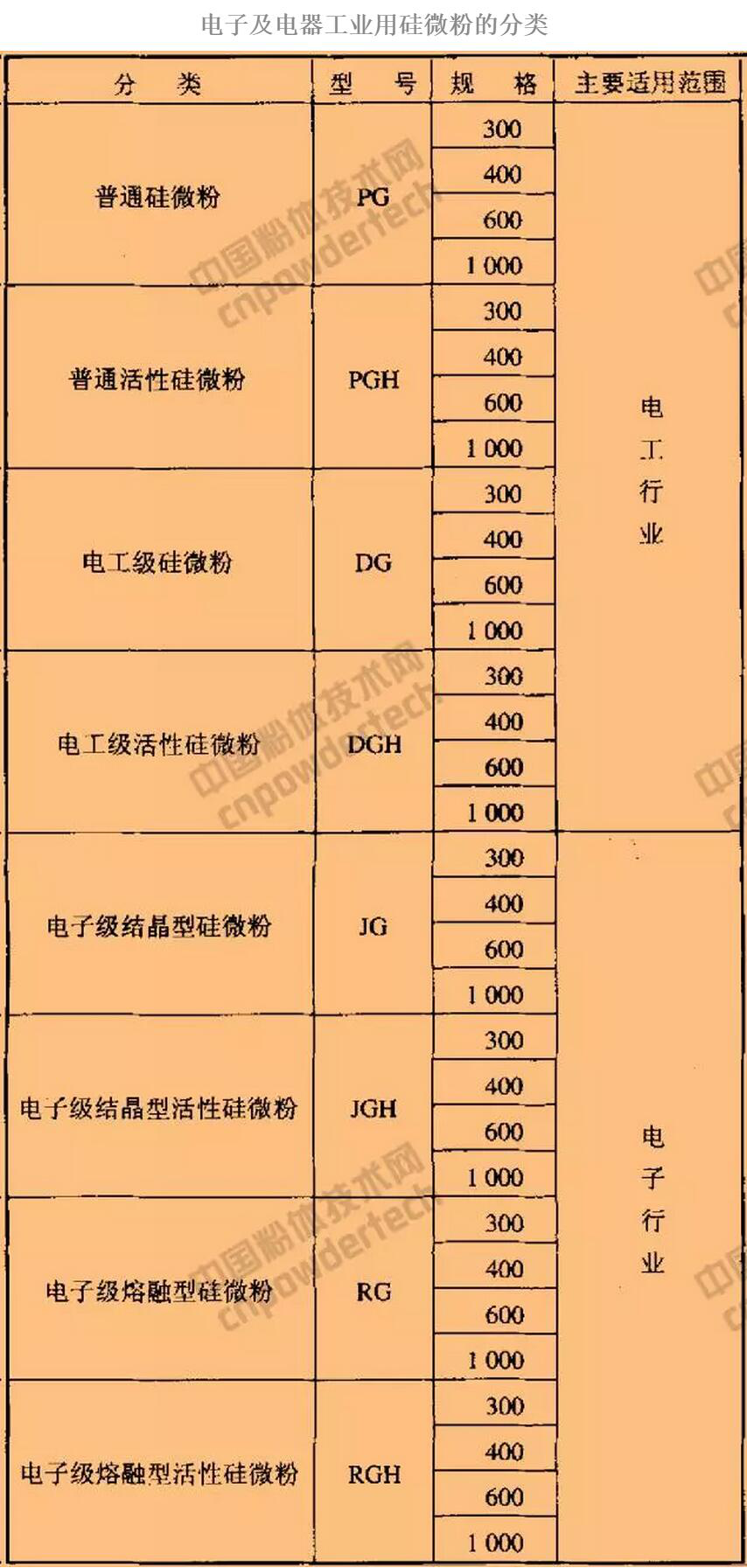

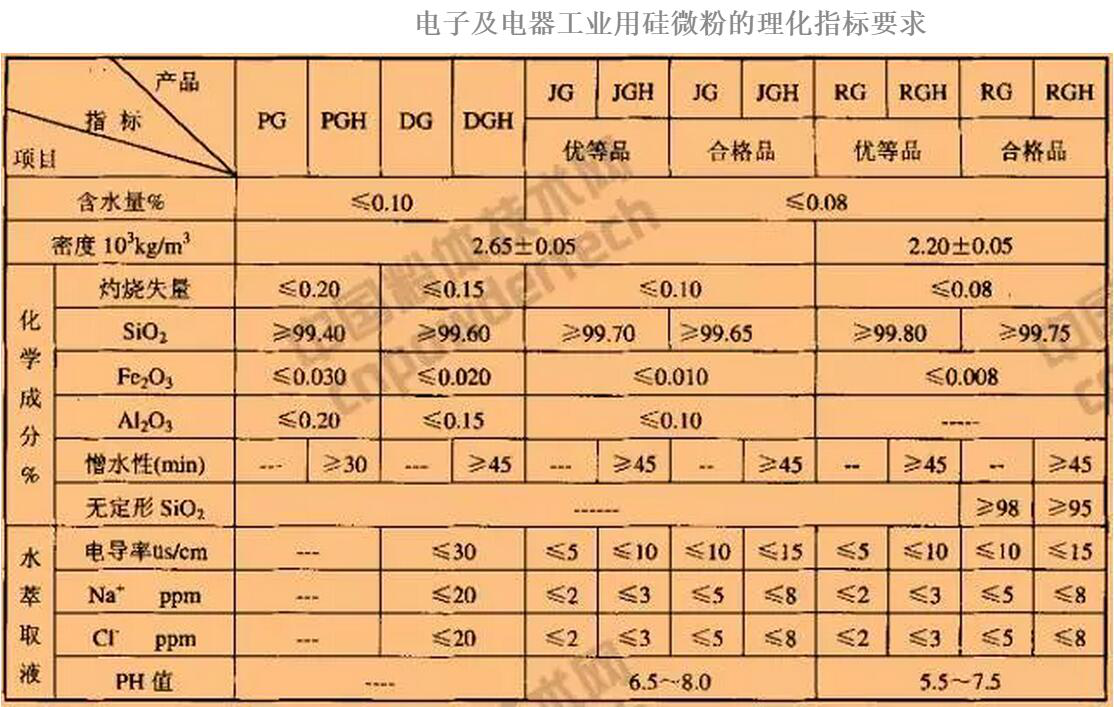

The "SJ/T 10675-2002 Silicon Dioxide Micropowder for Electronic and Electrical Industry" divides silicon micropowder into ordinary silicon micropowder, ordinary active silicon micropowder, electrical grade silicon micropowder, electrical grade active silicon micropowder, electronic grade crystalline active silicon micropowder, electronic grade molten silicon micropowder, and electronic grade molten active silicon micropowder.

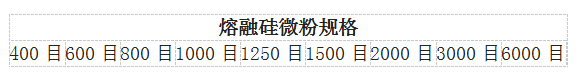

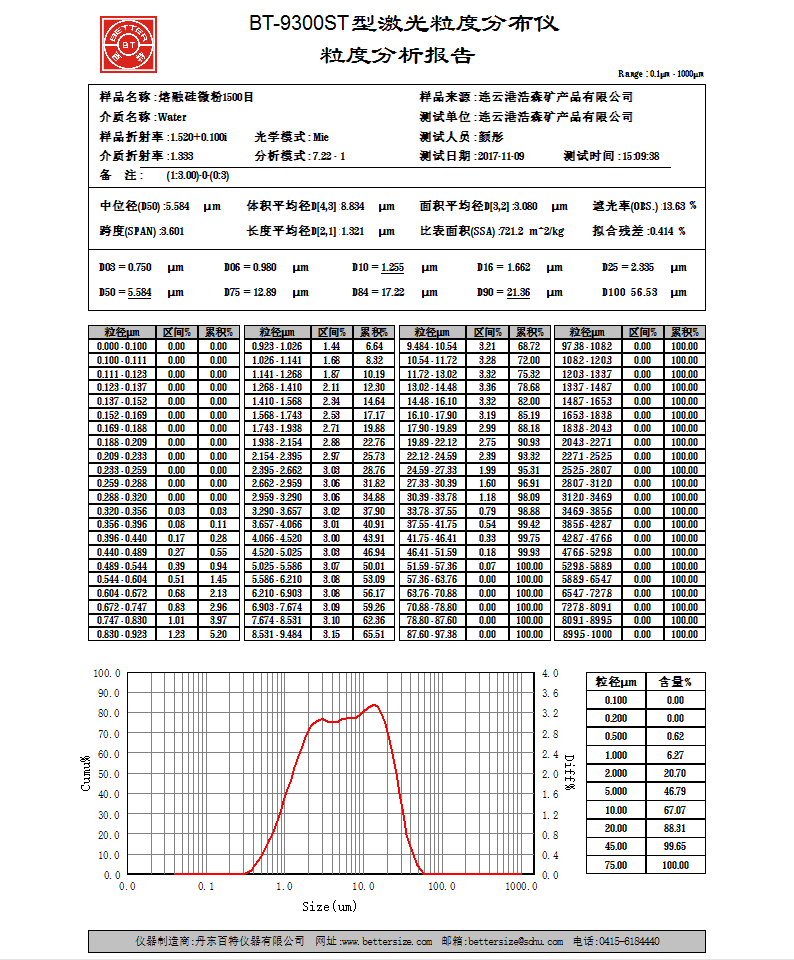

Lianyungang Haosen adopts advanced production processes such as high-quality quartz stone, water washing, damage, sun drying, drying, impurity removal, compounding,

melting dry ball milling, classifier grading, impurity removal, compounding mixing, packaging and warehousing. At present, it has developed and produced more than 30 specifications

of silicon micro powder products, including crystalline silicon micro powder, molten silicon micro powder, active (modified) silicon micro powder, high-purity silicon micro powder,

soft composite silicon micro powder, electronic grade silicon micro powder, electrical grade silicon micro powder, ultra-fine silicon micro powder, spherical silicon micro powder, glass powder,

cristobalite powder, high-purity quartz sand, fused silica sand, etc There are hundreds of different industries, including dental materials, precision casting, paint coatings, functional rubber,

plastics, chemical materials, nanomaterials, and advanced building materials. The product marketing covers more than 20 provinces and regions across the country, as well as exported to

countries such as Asia, Europe, the United States, and Africa.

Lianyungang Haosen has strong technical strength, advanced testing instruments, and a comprehensive pre-sale, in sales, and after-sales service system. We always adhere to the concept

of "quality is the life of the enterprise and innovation is the soul of the enterprise". Relying on the rich quartz mineral resources in Donghai County, we are committed to becoming the world's

leading supplier of industrial powder materials application solutions, and strive to provide customers with excellent products and services.

Lianyungang Haosen Mineral Products Co., Ltd

Contact person: Manager Xu 158 6125 0533

Manager Shi 152 5244 5528 177 5181 8818

Tel: 0518-87255528

Fax: 0518-87255528

Email: 923929950@qq.com

Website: www.lyghskc.com

Address: No.7, Xuhai West Road, Donghai County, Lianyungang City, Jiangsu Province